About

Who We Are

Founded in1998, Lead Seine has been dedicating to the manufacturing of nets.

立盛公司成立於1998年,致力於網具製造。

公司經營團隊來自於台灣各知名漁網公司,產業經驗超過40年。本公司立足於台灣市場奠基於專業投入的研發技術人員所生產出的高品質產品。立盛定位為專業無結網製造廠商,並根據客戶需求為其量身訂做各式網具。

本公司工廠位於南台灣的屏東縣,在整個生產程序中,採用嚴格的品管制度與方法以確保產品品質穩定,並準時交貨,為客戶提供高水準的產品與服務。目前立盛目前為台灣漁具製造公會活躍的會員。

本公司商標之上下,各有一條魚被漁網牢牢地圍繞纏裹,目的是傳達透過本公司優異的產品,期待讓客戶下網時不致遺漏任何漁獲。再者,兩條魚的涵義取材自聖經中耶穌以「五餅二魚」餵飽五千人的神蹟,立盛期待我們的客戶都能夠享受「立」刻使你漁獲豐「盛」的大豐收。

Competitive Advantages

Our major customers cover Taiwan military service, state enterprise, fishing boat owners, costal fisheries and sport goods distributors. According to customer satisfaction surveys and third-party evaluation, competitive advantage for Lead Seine lies in the knotless nets. Our competitive advantages highlight as four Cs:

本公司主要客戶包括政府國營事業、軍方、漁船業主、近海養殖戶與運動產品代理商。

根據客戶滿意度調查,本公司競爭優勢可用英文四個C開頭的字來表達:

Concentrate on Knotless Nets

專業無結網製造廠商

Cater and Care to Your Demand

滿足與關心客戶需求

Complete the “ Made in Taiwan” Legacy

承襲「台灣製造」的實力

Cherish the Sustainability

看重永續性

R&D

產品除應用於遠洋漁撈業,為因應近沿海養殖業的興盛,積極開發定置網及箱網市場。定置網的製作必須考慮海潮長年沖刷網具所導致的變形、掀起及脫落等問題。產品設計時即針對「網眼大小」、「網在水中的重量」及「網的強度」等指標參數,不斷測試開發,符合不同漁場、魚種及洋流需求的各式定置網。

箱網方面,本公司與科研機構合作開發新型材料,可防止藻類及浮游生物附著於網面,阻礙流水並滋生細菌。

由於運動網的需求越來越大,公司也致力把生產線擴大到運動用網,如足球網、棒球網、網球網或是羽球網。

品質是我們最主要關心的,提供給客戶高品質的網具是我們的責任,並且持續精進製網的技術來回饋給我們的客戶。

Market

According to customer satisfaction surveys and internal evaluation, the competitive advantage for Lead Seine lies in the knotless nets. Our R&D team applied the theorem of fluid dynamics, structural mechanics to come up with smooth, shiny and durable nets that might enhance the capability of stress and strain, particularly reduce the frictional resistance to reach faster sinking speed. Moreover, we are developing a new material for set nets and cage nets in a view to preventing the growing seaweed and plankton from cutting down the ocean current.

Due to the increasing demand for sports nets, the company also began to expand its production line to sports nets, such as football nets, baseball cage nets, tennis nets and badminton nets.

Quality is our main concern. It is our responsibility to provide customers with high-quality nets, and we continue to refine our net technology to give back to our customers.

一.主力產品:

產品主力為無結網,係運用流體力學的原理,設計出表面平滑的產品,可減少在海水中的摩擦力,使魚網在海中下沉速度變快,提高捕獲機率,並避免傷害魚身;其次,將結構力學運用於提升產品的拉扯力,產品品質深受軍事機關的認可與運動界的信賴肯定。

二.目標市場:

產品除應用於遠洋漁撈業,為因應近沿海養殖業的興盛,積極開發定置網及箱網市場。

定置網的製作必須考慮海潮長年沖刷網具所導致的變形、掀起及脫落等問題。

本公司產品於設計時即針對「網眼大小」、「網在水中的重量」及「網的強度」等指標參數,不斷測試開發,符合不同漁場、魚種及洋流需求的各式定置網。箱網方面,本公司與科研機構合作開發新型材料,可防止藻類及浮游生物附著於網面,阻礙流水並滋生細菌。由於運動網的需求越來越大,公司也致力把生產線擴大到運動用網,如足球網、棒球網、網球網或是羽球網。品質是我們最主要關心的,提供給客戶高品質的網具是我們的責任,並且持續精進製網的技術來回饋給我們的客戶。

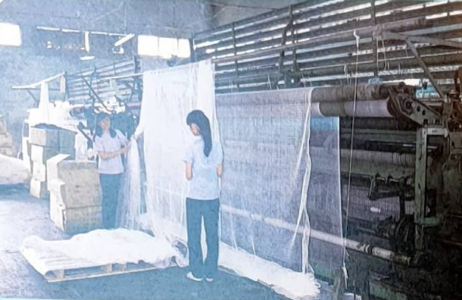

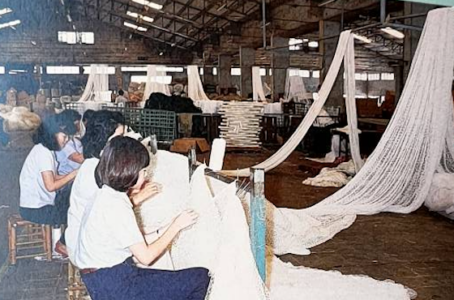

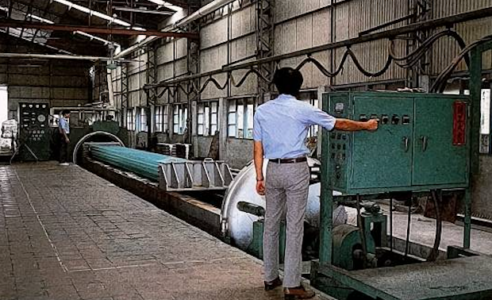

Production process

6